Sprayable Gels for Sun Care Applications

Anhydrous bases for spray-on suntan preparations are frequently used due to their innate water resistance and moisturization. These benefits can be enhanced with thickened anhydrous bases; however, these materials have historically exhibited instability and poor spray ability. This article will discuss a novel thickening technology that enables gelled anhydrous products to be delivered via a pump spray, while maintaining body, suspension or emulsion stability, and an acceptable spray pattern.

Since their development, personal care and household products that use trigger spray systems have become very popular with consumers in the US. Consumers- attracted by their functionality and ease of use – are very likely to buy and use these products. While many products sold in trigger sprayers are water-based (e.g., hard-surface cleaners), some emulsions and anhydrous products (such as suntan oils) are also available. One of the most attractive features of some of these products is their clarity, which is not surprising, since a clear product in a clear bottle implies purity and cleanliness (no residue).

Anhydrous Products

Anhydrous materials probably do not make up a significant percentage of trigger spray product formulations. Anhydrous fluids used in spray trigger products often are mineral oil-based, due to their low cost and ready availability. Mineral oil with a viscosity of 70 SUM at 100° F is frequently used for anhydrous personal care and sun care products, such as baby oils and tanning oils. In general, the finished products also have a low viscosity, below 100 SUS at 100° F. Higher viscosity oils are not recommended in these applications, since they tend to give a “heavy” feel on the skin.

For low viscosity anhydrous products, the types of trigger spray systems currently in use can deliver an excellent spray pattern; however, two major difficulties must be overcome:

When sprayed on a non-horizontal surface, a low viscosity liquid will drip, spill, or run down the surface. This leads to a poor coverage, wasting of the product, and low effectiveness in use.

As of October 25, 2002, the Consumer Product Safety Commission requires child-resistant (CR) packaging for certain products that contain low viscosity hydrocarbons. The requirement applies to certain prepackaged non-emulsion type liquid household chemical products, including drugs and cosmetics that contain at least 10% by weight of hydrocarbon and have a viscosity of less than 100 SUS at 100° F.(1)

Gel Products

Penreco has developed a patented technology for a series of gelled anhydrous liquids under the registered name of Versagel® for use in personal care. Versagel® products are sparkling clear, thermally reversible, anhydrous polymeric gels which can be created in an almost unlimited range of viscosities for each type of product.

Mineral oil is generally considered a Newtonian fluid, which means that the oil‘s viscosity does not change when shear stress is applied, By comparison, Versagel® products have viscoelastic, non-Newtonian properties. While most of these gels are shear thickening (rheopectic/dilatent) products, shear thinning (thixotropic/pseudoplastic) gels can be created by rigorous control of the polymer system.

Pseudoplastic materials instantaneously decrease in viscosity with an increase in shear rate (e.g., flow) and are therefore easier to pump and mix. They are also shear thinning; and they exhibit an instantaneous but temporary loss of viscosity with shear. The loss of viscosity with shear is often a consequence of high molecular weight molecules (such as polymers) being untangled and oriented by the flow. Generally, this behavior increases with concentration of the high molecular weight material, a particularly important feature for spray applications. Thus, low viscosity gels can be dispensed through a trigger spray nozzle due to their shear thinning properties. The gel will drop in viscosity as it passes through the spray trigger (shear stress) and rebuild viscosity when the stress ceases. For an application such as suntan oil, this shear thinning property will minimize drips and spills, while preventing the oil gel from spreading too far during application.

Another advantage is that a spray gel product will not require a child-resistant closure when the gel has a viscosity greater than 100 SUS at 100° F. This is particularly important since the mineral oil that is the major component of the gel has a viscosity lower than 100 SUS at 100° F. in addition, the gels will have a similar skin-feel as the oils from which they are made.

Finally, it is important to note that the suspension properties and emulsion stabilizing effects of gelled oils will be noticeably improved when compared to the corresponding ungelled oils.

Spray Patterns of Gels Compared to Mineral Oils

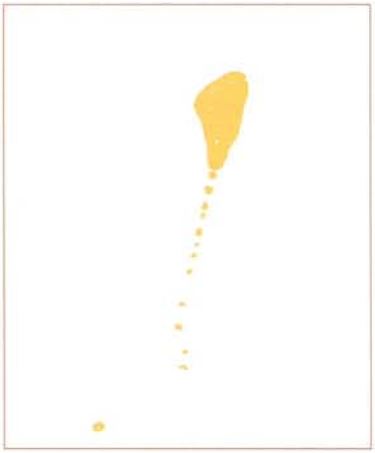

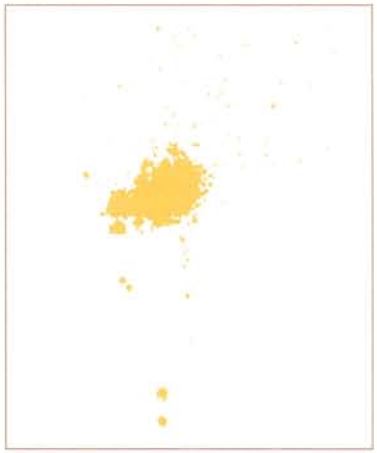

Spray pattern analyses have been conducted for gelled mineral oil versus ungelled mineral oil, where both products have the same viscosity, For example, a gel with a viscosity of 250 SUS at 100° F was compared with a mineral oil with the same viscosity. Since the polymer gellants increase the viscosity of mineral oil, an oil with a viscosity less than 250 SUS was gelled up to a viscosity of 250 SUS.

Figure 1 shows the spray pattern of the ungelled mineral oil, while Figure 2 shows the spray pattern of the gelled mineral oil. There is a noticeable difference between the two spray patterns – the gel has a greater spreadability as a result oi its ability to thin when sheared by the spray trigger mechanism. The ungelled oil does not thin when sheared, resulting in a spray pattern of less area.

Studies show that consistency is all important

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don’t look even slightly believable.

To take a trivial example, which of us ever undertakes laborious physical exercise, except to obtain some advantage from it? But who has any right to find fault with a man who chooses to enjoy a pleasure that has no annoying consequences, or one who avoids a pain that produces no resultant pleasure

Stay up to date on the latest regulations and requirements.

Sign up for our newsletter.

Press Releases & Articles

SHREVEPORT, LA – In May, Calumet will award four area high school […] INDIANAPOLIS, Feb. 28, 2025 /PRNewswire/ -- Calumet, Inc. (NASDAQ: […] Social Enterprise of Wheeler Mission Offers Handmade Candles made […] Initial loan proceeds of $782 million expected to be funded this […] Calumet produces a wide range of products for various industries. […] Click here to view this content on our Investor Relations site. Read […] Great Falls, MT – Montana Renewables LLC (MRL), the largest […]

Figure 1 – Ungelled Mineral Oil

Rheological measurements of the gel shown in Figure 2 indicate a 14% decrease in viscosity as the shear rate increases from 10 sec to 100 sec.

Figure 2 – Gelled Mineral Oil

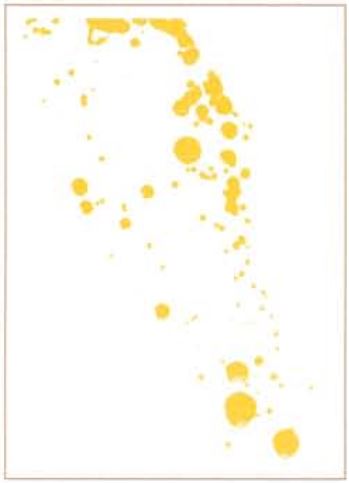

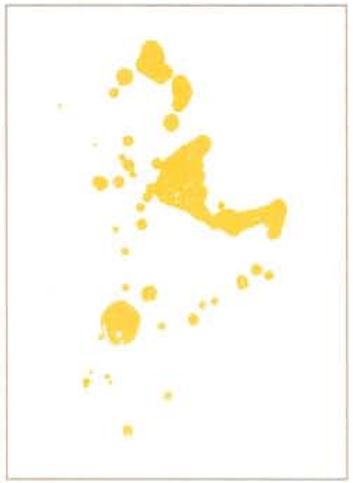

A second spray pattern experiment was conducted on a hydrocarbon gel, which has a viscosity of 600 SUS at 100° F (Figure 3) compared to a mineral oil with a viscosity of 600 SUS at 100° F (Figure 4). As expected, the gel had a better spray pattern.

Figure 3 – Hydrocarbon Gel (600 SUS)

Figure 4 – Mineral Oil (600 SUS)

In sunscreen formulations especially those formulated solely with chemical sunscreen active ingredients, solubility and polarity are very important. For these formulas, hydrocarbons are used only in limited amounts. Instead, long chain esters are often used as oil-phase emollients and moisturizers. Gelling these types of esters can minimize the dripping of these products as well.

Figure 5 – Gelled Isopropyl Palmitate

Figure 5 shows the spray pattern of a gelled isopropyl palmitate.

Conclusion

With trigger spray products gaining in popularity in personal care and household applications, using improved ingredients is becoming more important to both formulators and consumers. Pseudoplastic gels have great potential in spray trigger products because of their ability to drop in viscosity when shear stress is applied.

References

(1) See 16 CFR 1700.